James H Johnston

Victoria University of Wellington, New Zealand

Title: Nanostructured Calcium Silicate – A Novel “Green†Material Produced Sustainably from Geothermal Water and its Environmental Remediation and Industry Applications

Biography

Biography: James H Johnston

Abstract

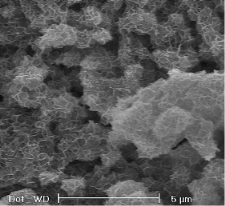

We have developed a novel green nanostructured calcium silicate material with excellent whiteness, chemical functionality and absorbent/adsorbent properties, from the problematic silica dissolved in separated geothermal water. It is an environmentally attractive material produced from a natural silica source with a low manufacturing energy footprint. This removal of silica from geothermal water also addresses the world-wide problem of unwanted silica deposition enabling more energy to be recovered from a geothermal resource. In geothermal electricity generation, sub-surface superheated geothermal water at about 250-350oC, saturated in dissolved silica, is piped to the surface where the pressure is reduced and some 30% is flashed into steam which drives a turbine to generate electricity. The remaining 70% of water cools to 100-130oC and becomes supersaturated in silica which precipitates out blocking pipework, heat exchangers and reinjection wells (Fig. 1). This is a major problem which limits energy recovery and results in high maintenance and operating costs. We have addressed this problem by producing a green nanostructured calcium silicate material, obviating silica deposition and enabling more energy to be recovered. The technology is being developed at pilot scale. Our approach, technology and novel green product offer significant commercial opportunities. We rapidly react the silica in the geothermal water to form nanostructured calcium silicate.This comprises nano-size platelets stacked together in an open framework structure forming discrete 1-5 μm particles (Fig. 2),with a high surface area which can be functionalized, and high absorbent and adsorbent properties. Potential applications of this naturally-sourced nanostructured calcium silicate material which we are developing include its use: as a functional filler in paint, tyres, plastics, paper, concrete and thermal insulation; in the recovery of dissolved phosphate from waterways and lakes, and base metals from mine waters; as a general absorbent and soil conditioning agent.

Recent Publications:

- Borrmann T, Johnston J H, McBrearty R (2009) Nano-Structured Calcium Silicate - A Solution to the Formation of Silica Scale in Geothermal Water. GRC Transactions 33:695-698.

- Gunnarsson I, Arnórsson S (2003) Silica Scaling: The Main Obstacle in Efficient Use of High-Temperature Geothermal Fluids. International Geothermal Conference, Reykjavík, Sept. 2003 Session #13, 30-36.

- Chan S H (1989) A review on solubility and polymerization of silica. Geothermics 18:49-56.

- Borrmann T, Johnston J H, McFarlane A J, McBrearty R (2005) Realizing Complete Silica Removal - Moving Technology from the Laboratory to Pilot Scale. GRC Transactions 4:996-998.

- Johnston J H, Borrmann T, Mcfarlane A J (2006) Nano-structured Calcium Silicate, Functionalised Forms Thereof, Preparation and Uses. NZ Patent 537747. (2006).

- Johnston J H, Mcfarlane A J, Borrmann T, Moraes J (2004) Nanostructured Silica and Silicates: New Materials and their Applications in Paper. Current Applied Physics 4:411-414.

- Cairns M J, Borrmann T, Johnston J H, Hoell W (2006) A Study of the Uptake of Copper Ions by Nano-structured Calcium Silicate, Microporous Mesoporous Mater. 95:126-134